OTHER AUXILIARY ITEMS

Home / Other Auxiliary Items

All Types Of Couplings & Pulleys

In mechanical systems, couplings and pulleys are essential parts that allow for effective motion control and power transfer. Pulleys make it easier to transfer power using belts or ropes, whereas couplings join two rotating shafts to transmit torque. The many kinds of couplings and pulleys, as well as their uses, benefits, and industrial applications, are thoroughly examined in this article.

All Types Of HTS & SS Bolt Nuts & V-Belts

V-belts and bolt nuts made of stainless steel (SS) and high tensile strength (HTS) are essential parts of many different industries. These parts guarantee strength, dependability, and effective power transmission in a variety of applications, including construction, machinery, and automobiles. The varieties, applications, and benefits of HTS & SS bolt nuts and V-belts are thoroughly examined in this article.

SS Braided Hose

SS braided hoses are essential components in a variety of industries, offering unmatched durability, flexibility, and performance. Whether in industrial systems, automotive applications, or residential plumbing, these hoses provide a reliable and efficient solution for fluid and gas transfer.

- Durability: The stainless steel outer layer protects against wear, abrasion, and external impact.

- Flexibility: These hoses can bend and flex without compromising their structural integrity.

- Pressure Resistance: Designed to withstand high-pressure applications without rupturing.

- Temperature Tolerance: Can handle extreme temperatures, from cryogenic to high-heat environments.

- Corrosion Resistance: Stainless steel provides excellent resistance to rust and chemical corrosion.

Cam Lock Hose Fittings

An essential component of fluid transfer systems, cam lock hose fittings provide dependability, effectiveness, and adaptability for a range of industries. You can guarantee smooth operations and maximize system performance by choosing the appropriate kind and material.

- Quick Connection: Enables fast assembly and disassembly without the need for tools.

- Leak-Proof Seal: Provides a secure and reliable connection to prevent fluid leakage.

- Versatility: Available in various sizes, materials, and types to suit different applications.

- Durability: Resistant to wear, corrosion, and environmental factors, ensuring longevity.

- Ease of Maintenance: Simple to clean and maintain for continued efficiency.

- Cost-Effective: Reduces downtime and enhances productivity in fluid transfer operations.

Belzona Metal Putty

Belzona Metal Putty is a ground-breaking product that has revolutionized how industries handle metal maintenance and repairs. For engineers and maintenance crews around the world, its unparalleled strength, adaptability, and simplicity of use make it a vital tool.

- High Adhesion: Forms a strong bond with a wide range of metals, including steel, aluminum, brass, and copper.

- Versatile Application: Suitable for repairing cracks, holes, and damaged surfaces, as well as creating durable seals.

- Corrosion Resistance: Provides excellent protection against moisture, chemicals, and harsh environmental conditions.

- Abrasion Resistance: Designed to withstand mechanical wear and impact.

- Temperature Tolerance: Performs effectively under extreme temperatures, depending on the type of putty used.

- Non-Shrink Formula: Cures without shrinking or deforming, ensuring a consistent and reliable repair.

TC Clamps

TC clamps are essential for preserving safe, leak-proof connections in industrial and sanitary systems. They are an essential equipment in many different industries because of their straightforward design, convenience of use, and hygienic qualities. Selecting the appropriate TC clamp may increase system efficiency, save downtime, and guarantee safety whether you work in the food processing, pharmaceutical, biotechnology, or chemical processing industries.

- Hygienic Design: TC clamps are designed to be easy to clean, ensuring they maintain sanitary conditions and reduce the risk of contamination.

- Quick and Easy Installation: Unlike welded or bolted connections, TC clamps can be quickly installed and removed without special tools, saving time during maintenance and repairs.

- Leak-Proof Seals: The combination of a gasket and a tight clamp connection ensures that the system remains leak-free, which is essential in industries dealing with liquids and gases.

- Corrosion Resistance: TC clamps made from stainless steel are highly resistant to rust and corrosion, making them ideal for use in challenging environments.

- Durability: Designed to withstand high-pressure and high-temperature conditions, TC clamps offer long-lasting performance in demanding applications.

- Versatility: Available in various sizes, materials, and designs, TC clamps can be used in a wide range of applications, from small-scale lab settings to large industrial systems.

Level Indicators

In many industrial applications, level indicators are crucial to the accurate, safe, and efficient monitoring of materials. Based on the type of material, the environment, and the level of accuracy required, businesses can choose from a variety of level indicators, each of which is appropriate for a particular purpose. Industries can boost operating efficiency, enhance safety, and optimize processes by utilizing these gadgets.

- Increased Accuracy: Level indicators provide precise measurements, reducing errors in material handling and improving process control.

- Improved Safety: By preventing overflows and underfills, level indicators help minimize accidents and improve safety.

- Enhanced Efficiency: Accurate level measurements allow for better inventory management, process optimization, and reduced downtime.

- Cost-Effective: Automated level measurement systems reduce the need for manual checking, saving time and labor costs.

- Real-Time Monitoring: Continuous monitoring ensures that any variations in material levels are detected and addressed immediately.

- Versatility: Level indicators can be used for a wide range of materials, from liquids and gases to powders and granular substances.

O – Rings

O-rings are straightforward but remarkably efficient sealing parts that are vital to many different industries, guaranteeing the integrity and security of systems that deal with liquids, gases, and solids. Industries can choose the best O-ring for their particular requirements by being aware of the many kinds, compositions, and uses. O-rings offer dependable, reasonably priced sealing solutions that enhance operational efficiency and safety in a variety of industries, including the automotive, aerospace, chemical, and food and beverage sectors.

- Cost-Effective: O-rings are relatively inexpensive compared to other sealing solutions, making them a cost-effective choice for a wide range of applications.

- Versatile: O-rings are available in various materials, sizes, and designs, making them suitable for a broad spectrum of industries and applications.

- Reliable Sealing: O-rings provide a highly effective seal, preventing leaks and contamination in critical systems, which enhances the safety and efficiency of operations.

- Durable: Made from durable materials, O-rings offer long-lasting performance, even in harsh environments with high pressure, temperature, or chemical exposure.

- Easy to Install and Replace: O-rings are easy to install and replace, reducing downtime and maintenance costs.

- Wide Temperature Range: Depending on the material, O-rings can operate across a wide range of temperatures, making them versatile for various conditions.

Air Filters

In a variety of applications, air filters are crucial for preserving clean air, safeguarding machinery, and creating a healthy atmosphere. Making the best choice for your requirements can be facilitated by being aware of the many kinds of air filters and their unique purposes.

- Improved Air Quality: Air filters remove harmful particles, allergens, and pollutants, leading to healthier indoor environments.

- Enhanced Equipment Performance: By preventing dust and debris from entering equipment, air filters help maintain optimal performance and reduce the risk of breakdowns.

- Energy Efficiency: Clean air filters allow for better airflow, reducing the energy consumption of HVAC systems and other equipment.

- Extended Equipment Lifespan: Regular use of air filters can prolong the lifespan of HVAC systems, engines, and industrial machinery by preventing damage from contaminants.

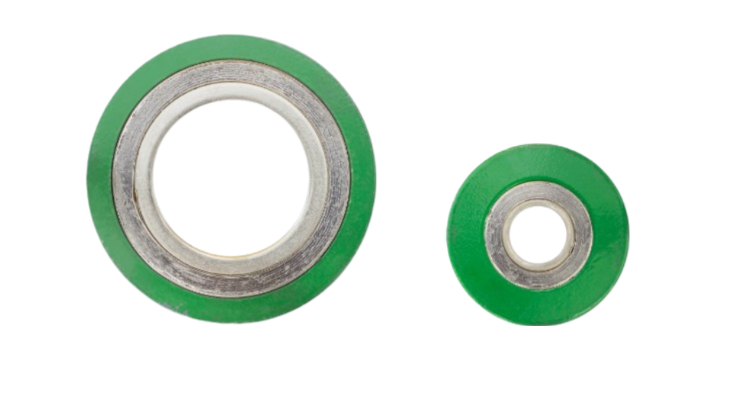

Spiral Wound Gaskets

For sealing high-pressure and high-temperature applications in a variety of sectors, spiral wound gaskets offer a dependable and adaptable option. They are a popular option for crucial applications where efficiency and safety are crucial due to their exceptional sealing performance, distinctive design, and versatility.

- Metal Winding: The metal strip, typically made from stainless steel, Inconel, Monel, or titanium, provides mechanical strength and resists corrosion.

- Filler Material: Common filler materials include graphite, PTFE (polytetrafluoroethylene), and mica, which offer excellent sealing properties and resistance to temperature and chemical attack.

- Outer Ring (Centric Ring): Provides proper gasket alignment within the flange and protects against over-compression.

- Inner Ring: Enhances gasket stability and protects the winding from thermal and chemical degradation.

PTFE/GFT/BFT Gaskets

For a variety of industrial applications, PTFE, GFT, and BFT gaskets provide dependable and adaptable sealing solutions. You may choose the best gasket for your requirements by being aware of the special qualities and benefits of each material, which will guarantee maximum effectiveness, safety, and performance.

- Chemical and Petrochemical Industry: Sealing aggressive chemicals and corrosive fluids in pipelines and reactors.

- Pharmaceutical and Food Industry: Ensuring hygienic sealing in processing equipment.

- Aerospace and Electronics: Providing insulation and sealing in high-tech applications.

- Oil and Gas Industry: Sealing high-pressure pipelines, valves, and flanges in refineries and offshore platforms.

- Power Generation: Sealing turbines, heat exchangers, and boilers in power plants.

- Chemical Processing: Handling aggressive media in reactors, pumps, and compressors.

- Pharmaceutical Industry: Sealing sterile processing equipment and pipelines in pharmaceutical manufacturing.

- Food and Beverage Industry: Providing hygienic sealing solutions for food processing and packaging equipment.

- Aerospace Industry: Sealing components in high-temperature and high-pressure aerospace applications.

PTFE/GFT/BFT Bushings

In a variety of industries, PTFE, GFT, and BFT bushings provide dependable and adaptable solutions for lowering friction, cushioning shocks, and directing moving parts. You may choose the best bushing for your particular requirements by being aware of the special qualities and benefits of each material, guaranteeing maximum effectiveness, safety, and performance.

- Chemical Processing Equipment: Bushings in valves, pumps, and agitators exposed to aggressive chemicals.

- Aerospace Industry: Reducing friction and wear in high-speed, high-temperature environments.

- Food and Beverage Industry: Ensuring hygienic operation in food processing machinery.

- Automotive Industry: Bushings in suspension systems, steering components, and engine mounts.

- Industrial Machinery: Heavy-duty bearings and bushings in conveyors, presses, and machining centers.

- Power Generation: Bushings in turbines, generators, and heat exchangers.

- Pharmaceutical Industry: Precision bushings in mixers, blenders, and tablet presses.

- Food Processing: Hygienic and durable bushings in food packaging and processing equipment.

- Aerospace and Defense: High-performance bushings in aircraft components and defense systems.

Oil Seals

Oil seals are crucial parts that guarantee the dependable and effective operation of machinery in a variety of sectors. You may improve your equipment’s longevity, performance, and safety by choosing the appropriate type and material, installing it correctly, and routinely servicing the seals.

- Sealing Lip: Made from elastomers like nitrile rubber (NBR), fluoroelastomer (FKM), or silicone, the lip maintains contact with the shaft to create a tight seal.

- Metal Case: Provides structural integrity and ensures a secure fit within the housing.

- Garter Spring: Enhances the sealing efficiency by maintaining consistent radial pressure on the shaft.

SS & MS GLR C-Clamps

With dependable clamping solutions for use in metalworking, automotive, construction, and other fields, SS and MS GLR C-clamps are essential instruments in many different industries. There is a GLR C-clamp that is appropriate for your needs, regardless of whether you need the strength and affordability of mild steel or the corrosion resistance and longevity of stainless steel. You may choose the best clamp to improve the effectiveness and security of your operations by being aware of the distinctions between SS and MS clamps and taking your unique application requirements into account.

- Frame: The body of the C-clamp, usually in a “C” shape, is designed to withstand the pressure and force applied during clamping.

- Screw Mechanism: The screw allows the clamp to be tightened around the object, creating a secure hold.

- Clamping Pad: Located at the end of the screw, the clamping pad is designed to make contact with the material being clamped and distribute pressure evenly.

- Throat Depth: The depth of the “C” shape of the clamp determines how far the clamp can reach to grip materials.

- Handle: The handle is used to tighten or loosen the screw mechanism, providing ease of use during operation.